Hon. Director Madam addressing students of TY Mechanical regarding Internship conducted by Chinese company Anet in collaboration with MGM’s College of Engineering, Nanded on 3-D Printer.

3-D Printer

|

Year

|

Name of the workshop/ seminar

|

Number of Participants

|

Date

|

|

2019-20

|

Seminar on Industry 4.0 factories of future by Dr. B.K. Buktar HOD Mech., Sardar Patel College of Engg. Mumbai.

|

114

|

16/08/2019

|

|

2019-20

|

A workshop on BMW Engine Dignosis by Rakesh Sharma, Abhyuday-Social body of IIT-Bombay

|

36

|

15 & 16-10-2019

|

|

2019-20

|

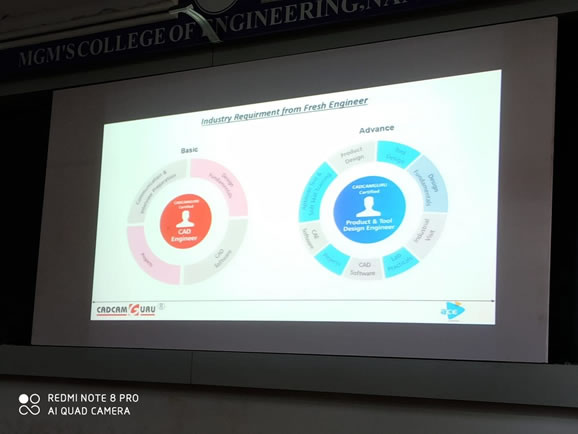

A seminar on Job Opportunity in CAD-CAM by by Mr. Akshay Joshi,CAD-CAM-GURU Solutions, Pune

|

122

|

02/03/2020

|

|

2019-20

|

A Webinar on Placement opportunities for Mechanical Engineering students by Prof. Pramod Dastoorkar, head Coroporate Relations-MIT, AOE, Pune

|

137

|

26/06/2020

|

|

2019-20

|

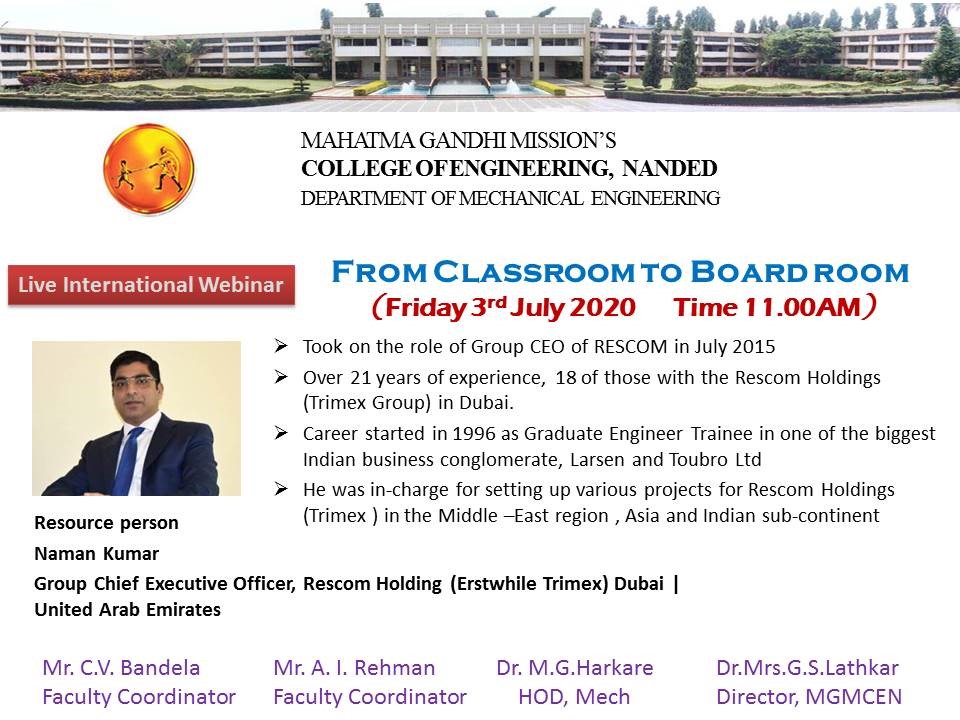

A webinar on from Class Room to Board Room, Mr. Naman Kumar, Group Chief Executive Officer, Rescon Holding(Erstwhile Trimex) Dubai, UAE

|

112

|

03/07/2020

|

|

2019-20

|

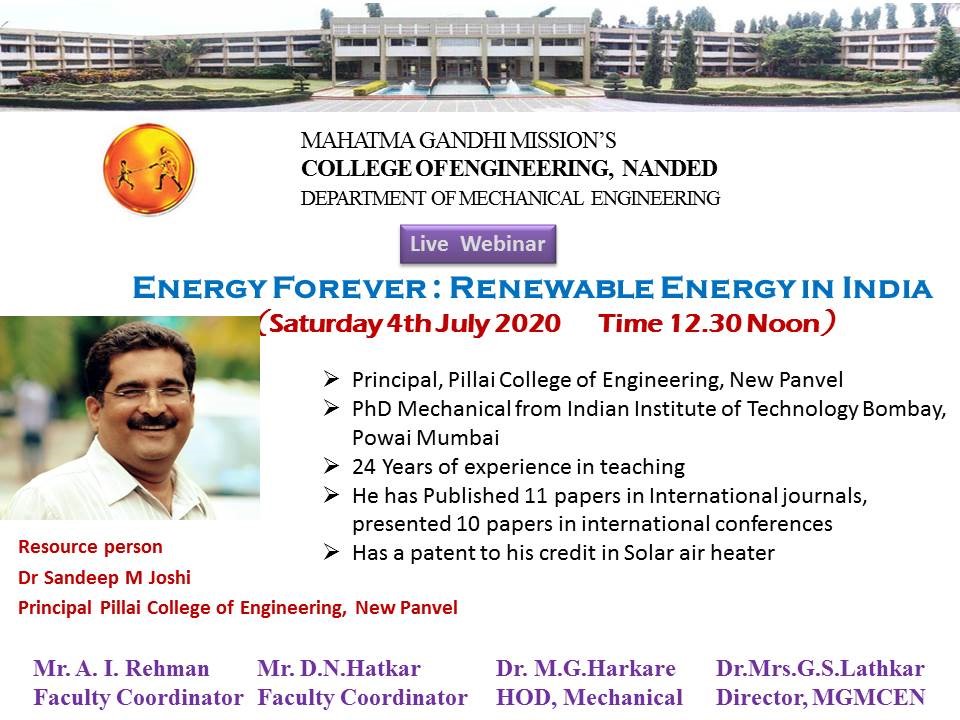

A webinar on Energy Forever:Renewable Energy India, by Dr. Sandeep Joshi, Principal, Pillai College of Engineering, New Panvel

|

96

|

04/07/2020

|

|

2019-20

|

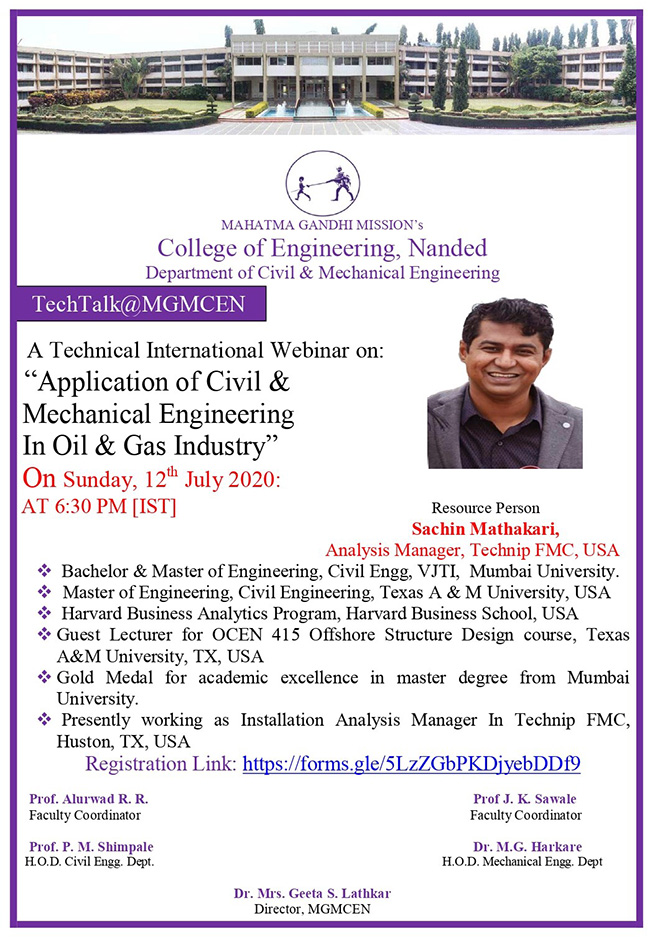

A webinar on Application of Civil and Mechanical Engineering in Oil & Gas Industry by Mr. Sachin Mathkari, Analysis Manager, Technip FMC, USA

|

281

|

12/07/2020

|

|

2019-20

|

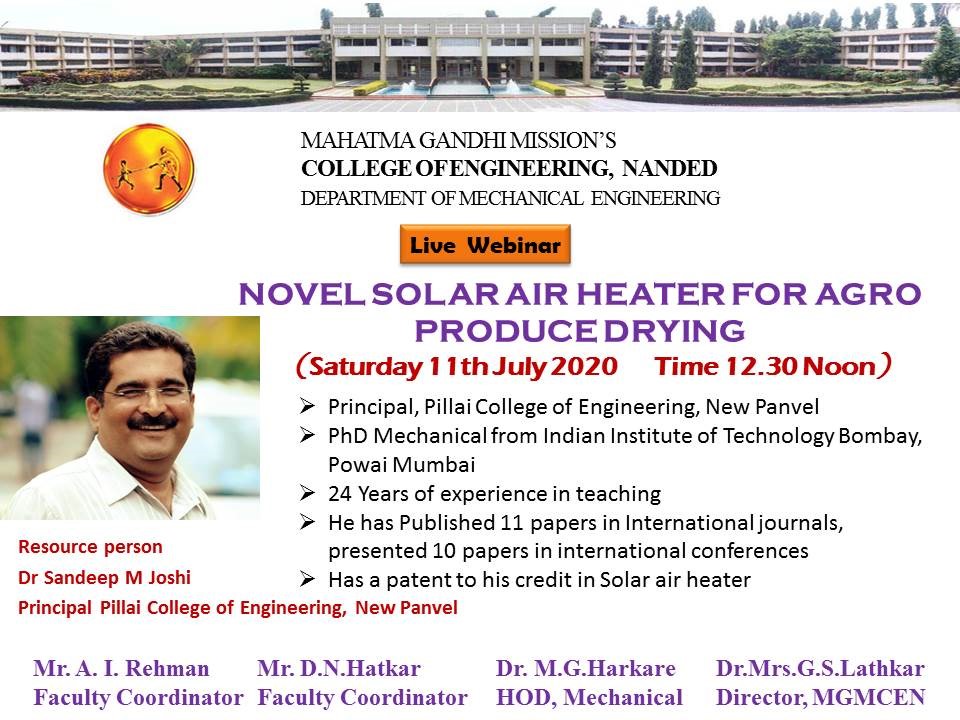

A webinar on Novel Solar Air Heater for Agro Produce Drying by Dr. Sandeep Joshi, Principal, Pillai College of Engineering, New Panvel

|

85

|

11/07/2020

|

Expert Lecture by Mr. Akshay Joshi from CAD-CAM- GURU, Pune

CAD-CAM- GURU

TPO Meet by INFOSYS at Ch. Shahu College of Engineering, Aurangabad.

BMW Training at Mumbai on 19th Nov.2019

Govt. Poytechnic students completed their Practicals of Material Sceience Engineering at Our Metallurgy Lab.

Govt. Poytechnic students introduce to CNC Machines

Expert Lecture on Industry 4.0 by Dr. B.K. Bhutkar, HOD Mech., Sardar Patel College of Engg. Mumbai

Expert Lecture on Softskills by Mr. P.K. Zarimeri.

Seminar on Advanced Refrigeration by Prof. S.N. Sapali, Govt. College of Engineering, Pune on 5thApr 2017.

A Seminar on Advanced Refrigeration by Prof. S.N. Sapali was organized in M.G.M’s College of Engineering, Nanded on 5th April 2017 .This Seminar was organized for BE Mechanical. He interacted with students related to advances in Refrigeration.

Prof. S.N. Sapali had given the information & discuss the following importance of Refrigeration with the students:

-

Probably the most widely used current applications of refrigeration are for air conditioning of private homes and public buildings, and refrigerating foodstuffs in homes, restaurants and large storage warehouses. The use of refrigerators in kitchens for storing fruits and vegetables has allowed adding fresh salads to the modern diet year round, and storing fish and meats safely for long periods. Optimum temperature range for perishable food storage is 3 to 5 °C (37 to 41 °F).

-

In commerce and manufacturing, there are many uses for refrigeration. Refrigeration is used to liquefy gases - oxygen, nitrogen, propane and methane, for example. In compressed air purification, it is used to condense water vapor from compressed air to reduce its moisture content. In oil refineries, chemical plants, and petrochemical plants, refrigeration is used to maintain certain processes at their needed low temperatures (for example, in alkylation of butanes and butane to produce a high octane gasoline component). Metal workers use refrigeration to temper steel and cutlery. When transporting temperature-sensitive foodstuffs and other materials by trucks, trains, airplanes and seagoing vessels, refrigeration is a necessity.

-

Dairy products are constantly in need of refrigeration, and it was only discovered in the past few decades that eggs needed to be refrigerated during shipment rather than waiting to be refrigerated after arrival at the grocery store. Meats, poultry and fish all must be kept in climate-controlled environments before being sold. Refrigeration also helps keep fruits and vegetables edible longer.

Seminar on Sustainable energy by Prof. D. L. Waikar, EduEnergy Consultant LLP, Tacstrasolutions Pte. Ltd. International Energy Foundation, Republic of Singapore on 7th Oct 2016.

A Seminar on Sustainable energy by Prof. D. L. Waikar, was organized in M.G.M’s College of Engineering, Nanded on 7th Oct 2016 .This Seminar was organized for TE, BE students of Mechanical Department & all Faculty member of MGM’s College of Engineering Nanded.. He interacted with students & faculty members of the department.

Prof. D.L. Waikar was given the information to the students as well as staff regarding Sustainable Energy and its objectives & benefits.

Objectives:

-

To advance the idea of Sustainable Energy..

-

To highlight the future trends of development of Sustainable Energy.

-

To determine the gaps in policy and legislation in furthering the ambition of Sustainable Energy.

-

To elucidate the prospects of Tidal and Geothermal Energy and determine their feasibility.

-

To strengthen the opinion on development and growth of Nuclear Energy as a fully sustainable method of generating clean energy.

-

To put forth a well balanced opinion on the policy-trends regarding realization of Sustainable Development Goals.

Benefits:

-

India is heavily dependent on coal, which is a main source of the greenhouse gases driving global warming.

-

To shift to a low-carbon path requires more efficient use of coal, demand-side management of energy, development of carbon capture and storage, use of natural gas as a bridge fuel, and a ramping up of renewable energy sources such as wind, solar, and hydropower.

-

To accomplish the shift to low carbon, it is important to stress that the need is not just a question of fuels but also regulatory and functional challenges for the electricity sector, especially in providing modern energy access to all and in achieving development goals.

-

This Seminar shall provide the required forum for people from the legal and environmental background to express their views and opinions on the importance of development of Sustainable Energy and also deliberate on their future in India, keeping in mind the current policy and legislative trends.

Seminar on Micromachining by Prof. Kornel F. Ehmann, North - Western University, USA and Prof. Suhas Joshi IIT , Mumbaion 14th - 16th Dec 2015.

Objectives:

There is a growing demand for industrial products with increased number of functions and of reduced dimensions. Micro-machining is the most basic technology for the production of such miniature parts and components. Micro machining is defined as the ability to produce features with the dimensions from 1 m to 999 m or when the volume of the material removed is at the micro level. Lithography based micro-machining technology uses silicon as material to produce integrated circuitry components and microstructures. However, these methods, in general, lack the ability of machining three-dimensional shapes because of poor machining control in the Z axis. Fabrication using hard and difficult-to-machine materials such as tool steels, composites, super alloys, ceramics, carbides, heat resistant steels and complex geometries for demanding aerospace, mechanical or biomedical applications requires alternative novel methods.

In recent years, manufacturing industry has witnessed a rapid increase in demand for micro-products and micro-components in many industrial sectors including the electronics, optics, medical, biotechnology and automotive sectors. Examples of applications include medical implants, drug delivery systems, diagnostic devices, connectors, switches, micro-reactors, micro-engines, micropumps and printing heads. These micro-system-based products represent key value-adding elements for many companies and, thus, an important contributor to a sustainable economy (Brousseau et al. 2010). As a result of the current trend towards product miniaturization, there is a demand for advances in micro- and nano- manufacturing technologies and their integration in new manufacturing platforms. These platforms must enable both function integration (i.e. combination of different functions) and length-scale integration (i.e. mixing of the macro-, micro- and nano-dimensions) in existing and new products and, at the same time, their cost effective manufacture in a wide range of materials.

Workshop on Engineering Mechanics by Dr. Amitabha Ghosh Ex-Director, IIT, Kanpur on 23rd to 24th September 2015.

A Seminar on Engineering Mechanics by Dr. Amitabha Ghosh, was organized in M.G.M’s College of Engineering, Nanded on 23rd to 24th September 2015 .This Seminar was organized for All First Year students & for Faculty members related with Engg. Mechanics of MGM’s College of Engineering, Nanded.

Dr. Amitabha Ghosh, had given the lecture to the students as well as staff regarding Dynamics of Engineering Mechanics as per syllabus of SRTMU, Nanded.

Objectives:

This seminar teaches students how to apply Newtonian physics to analyses relatively simple physical mechanisms. - with some emphasis on commonly encountered engineering applications. It follows on from the Statics course, but considers systems that are not in equilibrium i.e. with velocity and acceleration. Some of the topics covered are pure kinematics (a mathematical description of motion only), while others are kinetic (determine motion in problems involving the concepts of force and energy). The course is restricted to 2-D (planar) mechanisms.

Benefits:

-

Understand basic kinematics concepts – displacement, velocity and acceleration (and their angular counterparts)

-

Understand basic dynamics concepts – force, momentum, work and energy;

-

Understand and be able to apply Newton’s laws of motion;

-

Understand and be able to apply other basic dynamics concepts - the Work-Energy principle, Impulse-Momentum principle and the coefficient of restitution;

-

Learn to solve dynamics problems. Appraise given information and determine which concepts apply, and choose an appropriate solution strategy.

Honorable Chairman Shri Kamalkishorji Kadam welcome respected Dr. Amitabha Ghosh.

Day 1:

-

Kinematics: Displacement, Velocity and Acceleration

-

Newton’s laws of motion

Day 2:

-

Dynamics- Force, Momentum, Work and Energy

-

Impulse-Momentum principle and the coefficient of restitution

Seminar on Micro/Macro Scale Manufacturing by Prof. Suhas Joshi, Department of Mechanical Engineering, IITBombay on 3rd April 2015.

A Seminar on Micro/Macro Scale Manufacturing by Prof. Suhas Joshi was organized in M.G.M’s College of Engineering, Nanded on 3rd April 2015 .This Seminar was organized for BE Mechanical. He interacted with students related to advances on Micro/Macro Scale Manufacturing.

Seminar on Nano-Technologyby Dr. H. Bagchi, Prof. Department of Mechanical Engg. Sinhgarh College of Engineering, Pune,on 20th Mar 2015.

Seminar on Leadership Qualities by Dr. H. Bagchi, Prof. Department of Mechanical Engg. Sinhgarh College of Engineering, Pune,on 19th Mar 2015.

A Seminar on Leadership by Dr. H. Bagchi was organized in M.G.M’s College of Engineering, Nanded on 19rd March 2015 .This Seminar was organized for Faculty Members. He interacted with staff related to Implement an effective leadership style.

Objectives:

-

Implement practical steps for self-improvement.

-

Master the fundamentals of leadership, Build confidence & Set long-term/visionary goals.

-

Understand how leadership styles affect team members and how to adjust those styles to gain commitment.

-

Build trust and reduce resistance to change.

-

Impact productivity and team effectiveness through sharpening your communication and interpersonal skills.

Benefits:

-

Increase productivity. The right, consistent leadership can increase the productivity of your people. ...

-

Retain your people. ...

-

Nurture future leaders. ...

-

Increase employee engagement. ...

-

Implement an effective leadership style. ...

-

Make better decisions.

-

This Seminar help staff to develop the essential skills to influence and motivate staff to achieve exceptional performance. Create and maintain an efficient, effective, and motivated team. Improve your ability to communicate with the team and your customers.

Seminar on Super Conductors by Dr. H. Bagchi, Prof. Department of Mechanical Engg. Sinhgarh College of Engineering, Pune, on 19th Mar 2015.

Objectives:

-

Superconductors carry current in a much more compact form than is possible with copper. That means that your wires, instead of being as thick as they are from the wall to your computer, would be as much as an order of magnitude smaller. That might not strike you as being a key component, because you don’t actually devote that much space to the wires [in an office]. But when you talk about supplying the power required in New York City, then you have a different matter. We’re approaching limits in the major cities of the world where it’s not possible to fit more wires. The energy flow is reaching its maximum, spatially constrained amount. That’s a critical planning issue.

-

Also important is the speed with which electricity can be directed toward one application or another. That has an immediate implication for the stability of the grid in shuffling power from one area to another when there’s a failure. They’re called fault limiters, and superconducting fault limiters are far superior.

-

Another application is in the cell phone industry. The cell phone industry requires what we call bandwidth—making available more lines of communication to more customers. That means you have to pack the conversations into a narrow region of frequency, frequency being the “conductor” of information. These conductors are described [in terms of] how much frequency is required, just [like the amount of wire] in the electrical analogy. So we call this bandwidth.

-

The superconducting application here is that filters made with superconductors can slice the bandwidth more precisely than conventional filters. So we can crowd more information to be transferred into the same bandwidth of frequency.

-

In the problem of developing superconductors, such that they will have an impact on our society, there are two aspects, the first of which is a basic understanding of the process. The second is taking advantage of that basic science [for] feasibility studies and eventually execution in the marketplace or in the societal context.

Seminar on Cryogenicsby Dr. K.G. Narayankhedkar, Director, VJTI, Mumbai on 19th Mar 2015.

Some applications of cryogenics:

-

Nuclear magnetic resonance (NMR) - NMR is one of the most common methods to determine the physical and chemical properties of atoms by detecting the radio frequency absorbed and subsequent relaxation of nuclei in a magnetic field. This is one of the most commonly used characterization techniques and has applications in numerous fields. Primarily, the strong magnetic fields are generated by super cooling electromagnets, although there are spectrometers that do not require cryogens. In traditional superconducting solenoids, liquid helium is used to cool the inner coils because it has a boiling point of around 4 K at ambient pressure. Cheap metallic superconductors can be used for the coil wiring. So-called high-temperature superconducting compounds can be made to super conduct with the use of liquid nitrogen which boils at around 77 K.

-

Magnetic resonance imaging (MRI) - MRI is a complex application of NMR where the geometry of the resonances is deconvoluted and used to image objects by detecting the relaxation of protons that have been perturbed by a radio-frequency pulse in the strong magnetic field. This is mostly commonly used in health applications.

-

Electric power transmission in big cities- It is difficult to transmit power by overhead cables in big cities, so underground cables are used. But underground cables get heated and the resistance of the wire increases leading to waste of power. Superconductors could be used to increase power throughput, although they would require cryogenic liquids such as nitrogen or helium to cool special alloy-containing cables to increase power transmission. Several feasibility studies have been performed and the field is the subject of an agreement within the International Energy Agency.

-

Frozen food - Cryogenic gases are used in transportation of large masses of frozen food. When very large quantities of food must be transported to regions like war zones, earthquake hit regions, etc., they must be stored for a long time, so cryogenic food freezing is used. Cryogenic food freezing is also helpful for large scale food processing industries.

-

Forward looking infrared (FLIR) - Many infra-red cameras require their detectors to be cryogenically cooled.

-

Blood banking -Certain rare blood groups are stored at low temperatures, such as -165 °C.

-

Special effects-Cryogenics technology using liquid nitrogen and CO2 has been built into nightclub effect systems to create a chilling effect and white fog that can be illuminated with colored lights.

-

Manufacturing process

Cryogenic cooling is used to cool the tool tip at the time of machining. It increases the tool life. Oxygen is used to perform several important functions in the steel manufacturing process.

-

Recycling of Materials -By freezing the automobile or truck tire in Liquid nitrogen, the rubber is made brittle & can be crushed into small particles. These particles can be used again for other items.

-

Research -Experimental research on certain physics phenomena, such as spintronics and magneto transport properties, requires cryogenic temperatures for the effects to be observed.